In an era where environmental consciousness is on the rise, sustainable alternatives to conventional materials are gaining prominence. One such innovation is Biofoam, a biopolymer that serves as a compelling substitute for polystyrene. This article delves into the myriad reasons why Biofoam should be embraced over polystyrene, emphasising its eco-friendly attributes, and highlighting its modest impact on the environment.

The Eco-Friendly Revolution: Biofoam’s Triumph Over Polystyrene

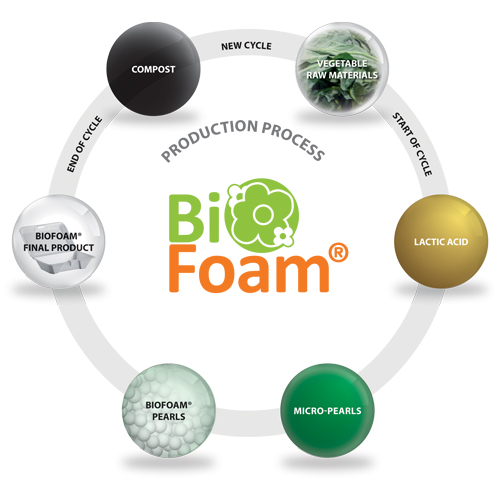

The shift towards more environmentally friendly materials has been spearheaded by the advent of Biofoam. Developed in the mid 2000’s and available on the market since 2007, this remarkable biopolymer is derived from plant extracts, setting it apart from the petroleum-based origins of polystyrene. The environmental implications of this distinction are monumental, considering the significant carbon footprint associated with the extraction and processing of fossil fuels for polystyrene production.

CO2 Neutrality in Manufacturing: A Gentle Footprint on the Planet

Biofoam boasts a key advantage that tilts the scales in favour of its adoption: its manufacturing process is inherently CO2 neutral. This means that the production of Biofoam does not contribute to the accumulation of greenhouse gases in the atmosphere. In contrast, the manufacture of polystyrene is energy-intensive and releases substantial amounts of carbon dioxide, exacerbating the global climate crisis.

By opting for Biofoam, industries can tangibly reduce their carbon footprint, playing a pivotal role in mitigating climate change and safeguarding the planet for future generations.

Biofoam’s Sustainable End-of-Life Solution: Composting

One of the most compelling reasons to choose Biofoam over polystyrene is its end-of-life solution. While polystyrene often lingers in landfills for centuries, contributing to an ever-growing waste problem, Biofoam offers a sustainable solution. Biofoam can be composted at high temperatures, breaking down into organic matter that enriches the soil.

Read our story on why we use Biofoam.

In stark contrast, polystyrene’s recalcitrance to decomposition perpetuates its harmful impact on the environment, with devastating consequences for wildlife and ecosystems. The choice to utilise Biofoam not only reduces waste but also actively contributes to the regeneration of natural resources.

Performance Parity: Strength and Durability

Addressing concerns about performance, Biofoam proves to be a worthy substitute for polystyrene. Offering a like-for-like comparison in terms of strength and durability, Biofoam ensures that the transition from polystyrene does not necessitate any compromise on product quality. Whether it is filling our bean bag products or providing structural support in various applications, Biofoam seamlessly adapts to diverse requirements.

This level of performance parity eradicates any reservations that may arise when considering a shift from traditional materials to more sustainable options.

Diverse Applications of Biofoam: Beyond the Bean Bag

Biofoam’s versatility extends far beyond being a mere alternative to polystyrene. The biopolymer’s unique properties make it suitable for a wide range of applications. One notable application is the filling of bean bags and similar items that have traditionally relied on polystyrene beads. By making this switch, manufacturers and consumers alike contribute to a cleaner environment without sacrificing comfort or utility.

The Environmental Toll of Polystyrene

To truly understand Biofoam’s advantages, it’s crucial to acknowledge the detrimental impact of polystyrene on the environment. Polystyrene, often recognised by its trademarked name “Styrofoam,” poses a significant threat to ecosystems, wildlife, and human health. Its lightweight structure makes it prone to becoming litter, polluting water bodies and landscapes. Marine life frequently mistakes small polystyrene particles for food, leading to ingestion and subsequent harm to the entire food chain.

Moreover, the non-biodegradable nature of polystyrene perpetuates its persistence in the environment, negatively impacting both terrestrial and aquatic ecosystems for generations.

Conclusion

The choice between Biofoam and polystyrene is more than just a business decision; it’s a statement about our commitment to the planet’s well-being. As consumers become increasingly conscious of the environmental consequences of their choices, industries have a responsibility to align their practices with sustainability goals.

Biofoam’s eco-friendly credentials, derived from plant extracts, CO2-neutral manufacturing, composability, and performance parity, position it as an undeniable contender in the race to replace polystyrene. By embracing Biofoam, we embrace a greener future, free from the ecological burdens associated with polystyrene’s harmful legacy. The transition to Biofoam isn’t just an upgrade in materials; it’s a pledge to safeguard the planet and preserve its beauty for generations to come.